Titomic Kinetic Fusion (TKF).

Material Innovations Expands Production Applications.

Titomic Kinetic Fusion (TKF).

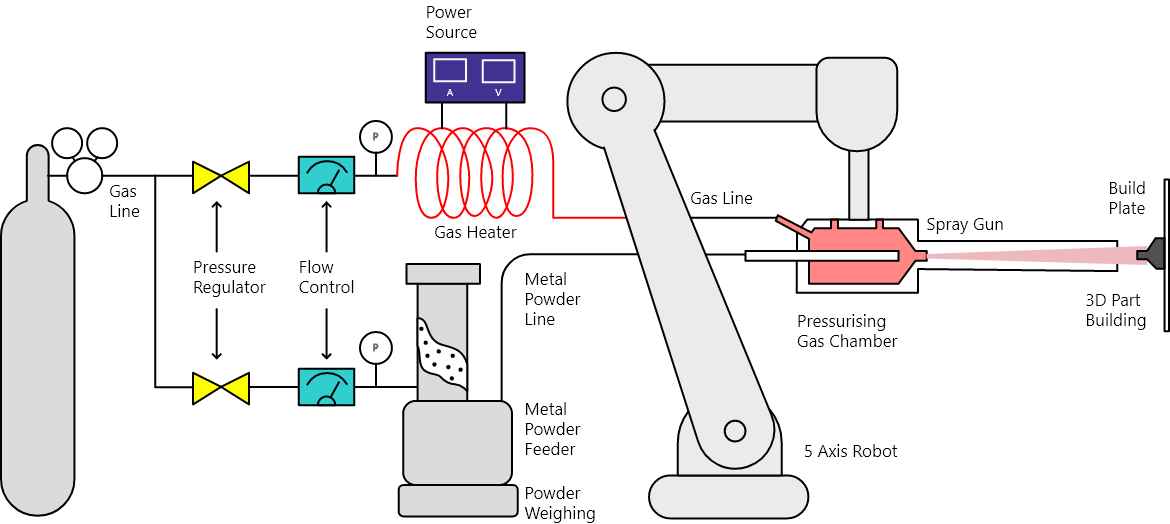

Titomic Kinetic Fusion, or TKF, utilizes the supersonic particle deposition of metal powders to create industrial-scale parts and complex surface coating.

Titomic Kinetic Fusion begins by accelerating metal particles to supersonic speeds by injecting them into a jetstream to additively manufacture metal parts. The particles exit the spray nozzle and upon colliding with the surface, they plastically deform, sticking to the surface and each other. The build-up of these particles rapidly develops into near-net-shape metal parts.

Titomic Kinetic Fusion Differentiators

- World’s fastest additive manufacturing build rates, unlocking industrial-scale additive manufacturing.

- World’s largest metal additive manufacturing, demonstrated by the TKF 9000 with a 9 x 3 x 1.5 metre build capacity.

- Fuse dissimilar metals to create composite metal parts, exploiting the strengths of multiple metals in a single part.

Titomic Kinetic Fusion Differentiators

| Material | Summary |

|---|---|

| Titanium and Titanium alloys, including Ti-Al6-4V, CP, and more | Data Sheet Get in touch |

| Steel | Data Sheet Get in touch |

| Copper | Data Sheet Get in touch |

| Nickel | Data Sheet Get in touch |

| Magnesium | Data Sheet Get in touch |

Alone you can go fast, Together you can go far

- African proverb

Let’s create future, together.