Rapid prototyping.

Material Innovations Expands Production Applications.

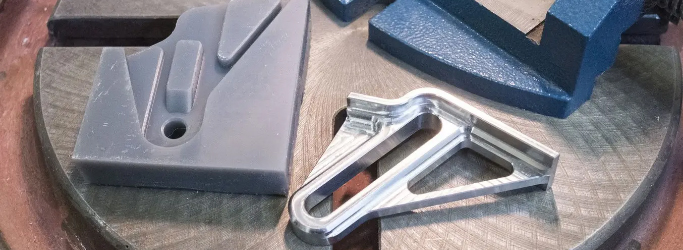

3D printing has been invented to rapidly fabricate physical models based on CAD designs.

Rapid prototyping is an answer to three major challenges businesses face in product development

- Iterating through multiple version of a design takes a lot of time andresources

- Outsourcing fabrication of prototypes comes with a risk of having thedesign leaked

- Using traditional manufacturing technologies for prototyping lengthen the time to market

Advantages of Rapid prototyping..

No lead times.

R&D staff can iterate through different designs rapidly which make their work more efficient.

In-house fabrication.

Prototypes are made entirely in-house which contributes to better intellectual property protection.

Short time to market.

Fast and efficient prototyping stage leads to shorter time to market, so a new product can bring in revenue sooner.

Limitless design.

3D printing is capable of producing shapes impossible to make with traditional manufacturing techniques.

Workflow in rapid prototyping.

-

Step 1.

CAD design.A new product is designed in a CAD software.

-

Step 2.

Digital pre-processing.A set of instructions for the 3D printer is created based on the CAD model.

-

Step 3.

3D printing.A model is automatically fabricated on a 3D printer.

-

Step 4.

Evaluation.A physical prototype can be used for testing or presented to stakeholders.

Rapid Prototyping helps design and turn ideas into reality quickly and efficiently, enabling real-time product design feedback and concept testing. It is a group of techniques used to quickly fabricate a scale model of a physical part or assembly using 3D CAD design data.

Rethink metal part design and produce products, components, and tools with reduced weight, increased functionalities, and simplified assemblies.

Save time, cost, and part weight with an integrated precision metal manufacturing solution of software, direct metal printing technology, certified materials, and expert application support.

From your office to the factory floor, our 3D printers generate plastic concept models, precision and functional prototypes, master patterns, and real end-use parts to optimize your designs, streamline your workflows, and bring innovative products to market faster.

From educational settings to the most demanding commercial environments, 3D Systems’ family of ProJet CJP x60 3D printers provides unparalleled color prototyping capabilities with exceptional print speeds, efficiency, and low costs of operation.

How 3D Printing Helped Design a Revolutionary Motorbike .

Prototyping Tools for Spacewalks How Zortrax Ecosystem Works at NASA .

Rapid Prototyping Pointing the Way for Automotive Innovation .

3D Rapid Prototyping Fast Tracks GM Fuel Efficiency Gains with 3D Systems .

Rapid SLA Prototyping With The New Draft Resin .