Ceramic.

Alumina.

Alumina is a commonly used fine ceramic material well-known for its high strength, corrosion and wear-resistance.

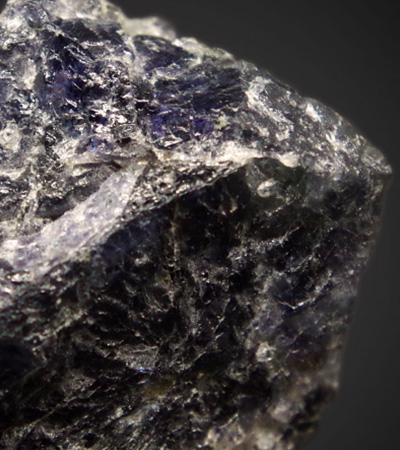

Zirconia.

Zirconia has the highest mechanical strength and fracture toughness at room temperature of all major fine ceramics.

Silicore.

A porous ceramic formulation with high mechanical resistance specifically developed for foundry cores.

Alumina Toughened Zirconia.

A composite ceramic material known for its biocompatibility, resistance to wear and thermal shock.

Cordierite.

Ceramics with good thermal shock resistance, low thermal expansion, low thermal conductivity, and high dielectric strength.

Zirconia 8Y.

Partially-stabilized zirconia powder with uniform dispersion of 3 mol % yttria.

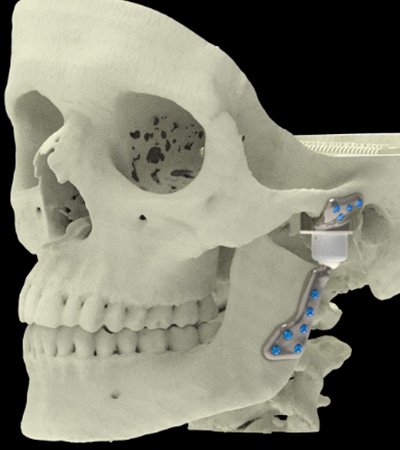

TCP.

Tricalcium Phosphate, a ceramic material often used for implants in the medical field, to recreate parts close to the structure of a spine.

Silice SiO2.

A high-purity grade of silica that has good abrasion resistance, electrical insulation and high thermal stability.

HAP.

Biocompatibility, bioactivity, osteo-conductivity, non toxicity and non inflammatory nature make this material best for biomedical applications.

Silicon Nitride.

This is among the hardest and most resistant technical ceramics with a high resistance to thermal shocks, to wear and corrosion.

Aluminium Nitride.

High mechanical properties of this ceramic, combined with high thermal conductivity and electrical insulation, are highly recommended in electronics industry.