Metal .

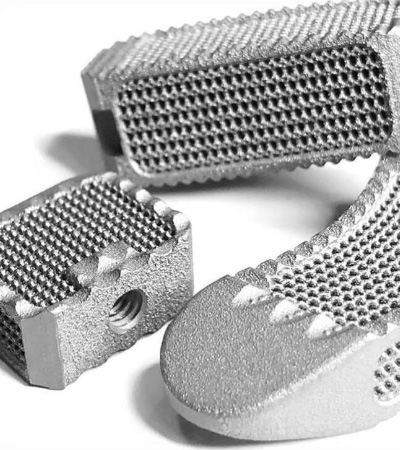

Titanium.

Alumina is a commonly used fine ceramic material well-known for its high strength, corrosion and wear-resistance.

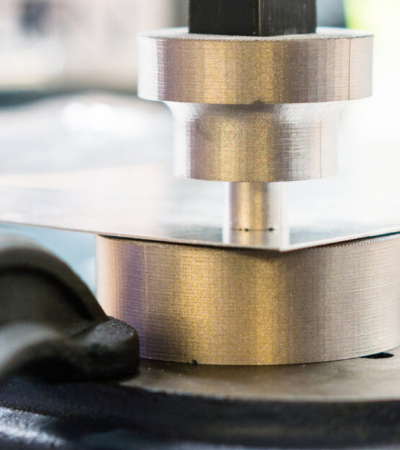

Stainless Steel.

An iron and chromium alloy with excellent corrosion resistance, high strength and attractive appearance.

Maraging Steel.

An ultra-high-strength steel alloy, that exhibit superior tensile strength, high toughness, high ductility, and high impact strength.

Cobalt-Chrome.

Cobalt-chromium (Co-Cr) alloys have high specific strength and are hard, tough, corrosion resistant, biocompatible metals.

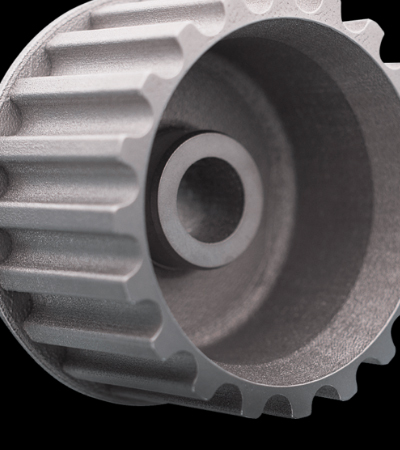

Aluminum Alloy.

A light-weight metal alloy with a combination of good thermal conductivity and mechanical properties.

Nickel Super Alloy.

An alloy with exceptional strength, and long fatigue life combined with good resistance to oxidation and corrosion at high temperature.

17-4 PH Stainless Steel.

A heat-treatable multipurpose steel used for industrial applications.

Inconel 625.

A nickel-chromium based superalloy, extremely resistant to corrosion & strong at high temperatures.

A2 and D2 Tool Steel.

Cold work tool steels optimized for cutting and forming tools or other applications where high hardness is required.