Automotive.

Material Innovations Expands Production Applications.

Prepare rapid prototypes as well as complex designs, & provide the Automotive Industry with innovation and proficiency in the supply chain.

3D printing combats automotive challenges in no time:

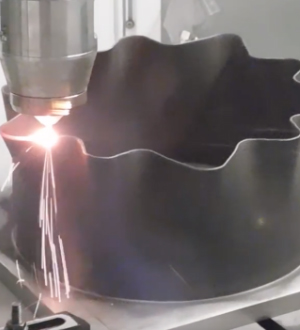

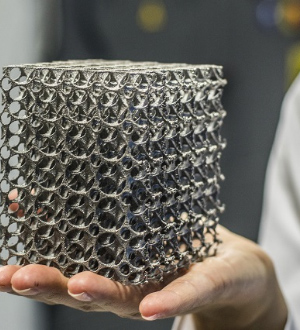

Metal 3D printing, provides a new approach to the current challenges of energy efficiency, high costs of raw materials that are faced by the automotive industry. It offers design freedom while allowing the creation of complex yet lightweight components. Automotive additive manufacturing enables the production of components without the need for tools, thereby cutting development and production costs.

With additive manufacturing, automotive manufacturers can target high level of innovation and performance in their products and increase the efficiency of their research & development, enabling them to get their vehicles to market quickly. Additive manufacturing is a disruptive and rapidly-growing technology that provides the automotive industry with innovation freedom, and proficiency in the supply chain. This technology can also be used for testing, manufacturing, and assembling automotive parts and components with higher efficiency, optimization, and cost-efficiency.

There are different additive manufacturing technologies that are developed according to specific components/areas/production requirements of the automotive industry like Fused Deposition Modelling (FDM), Stereolithography (SLA), Selective Laser Sintering (SLS), and Electron Beam Melting (EBM).

With this technology, automakers now have the capability to perform on-site fabrication to spur the maintenance and repair of automotive components, and at the same time, compile new business models by innovating and customizing the supply chain and products for improved market responses. For the automotive industry, these advances have opened doors for newer designs; cleaner, lighter, and safer products; shorter lead times; and lower costs.

The automotive industry has been witnessing exciting changes, such as shift from fuel-efficient and powerful vehicles to the onset of electric-powered vehicles. Increased demands for customization result in the need for automotive manufacturers to embrace additive manufacturing for low-volume production.

High-value automotive applications.

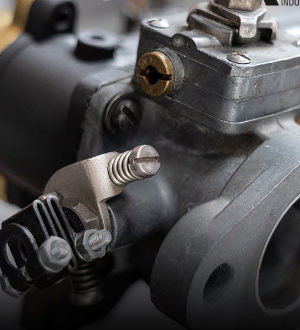

Under hood / Powertrain.

Body Interior & Trim, Body Exterior & Panel.

Metal Structural Components.

Manufacturing Aids.

Energy & Fluid Management (metals).

Metal Durable Tooling.

Durable, complex assembly jigs.

Lightweight grippers/ end-of-arm-tooling.

High-strength brackets and sensor mounts.

Functional prototypes.

Welding hardware: fixtures, shanks, splatter guards.

Ergonomic/fit prototypes.

Brazing fixtures.

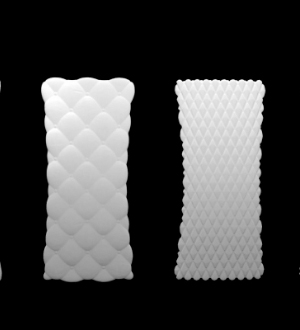

Variable Shelling.

Lattice infills.

Surface texturing.

Heat Exchangers.

Reverse-engineering automotive parts using metal 3D printing technology .

Sauber Engineering Chooses 3D Systems to Power Constant Innovation .

Impossible Creations Calls on 3D Systems’ Digital Workflow for the King’s Car .

Resin 3D Printing in Manufacturing of Automotive Parts .

Seatools Exhibits Quality with Appearance Models from 3D Systems On Demand Manufacturing .