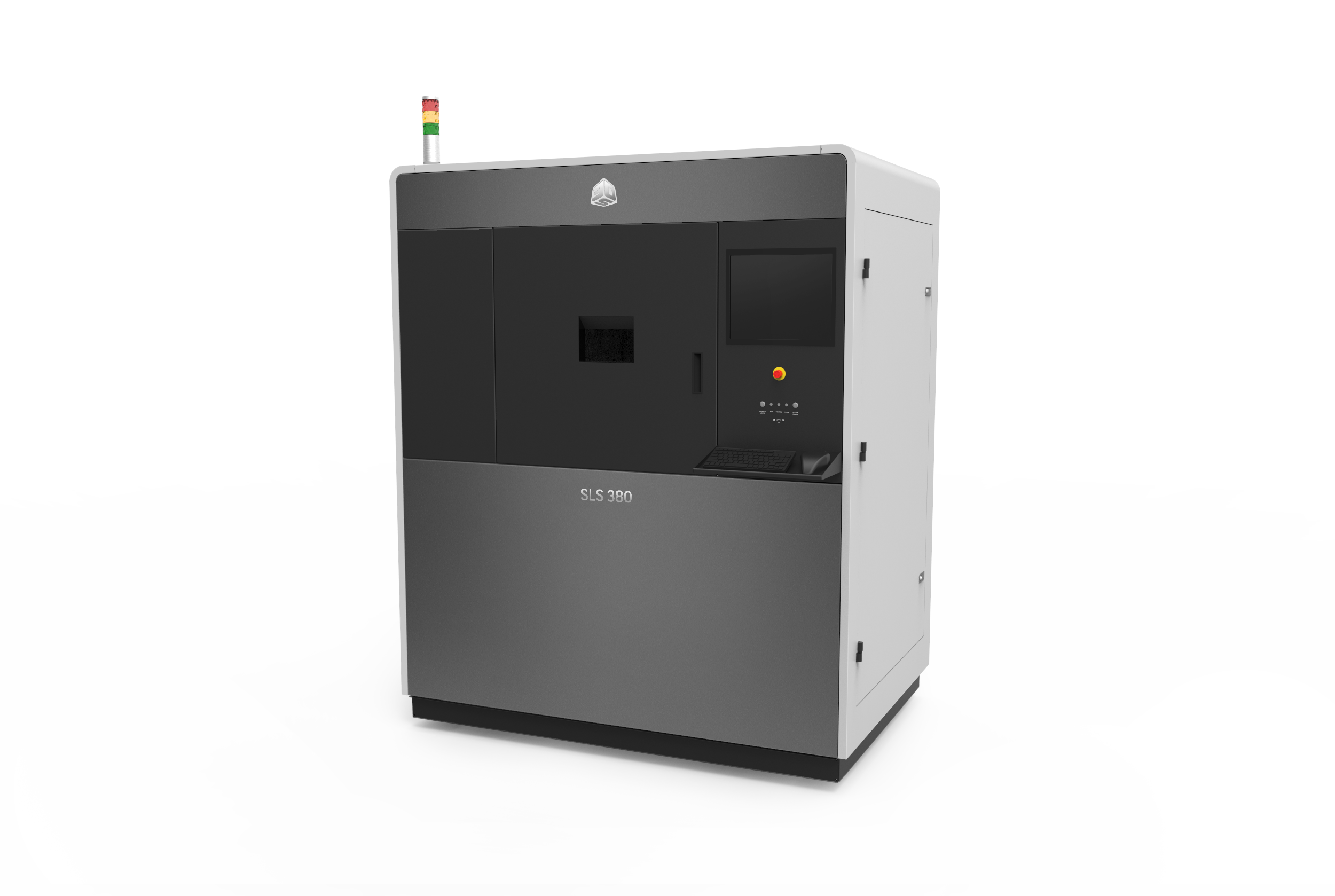

Selective Laser Sintering (SLS).

SLS 380.

Properties

Industrial-scale, process controlled additive manufacturing solution for selective laser sintering

Highlights

High throughput workflow solution with closed-loop process controls for repeatability across parts, builds, machines, and sites

Production-grade nylon thermoplastics

Automated 3D part nesting, material handling, and post-processing solutions

Software

3D Sprint

SLS 300.

Properties

Advanced SLS technology in a user-friendly format

Highlights

Prints highly detailed and functional parts with a wide range of materials

Exceptional accuracy and durability

Easy to use interface with the ability to print remotely

Software

Deep Space

Materials offered for SLS.

- Dura Form.

-

DuraForm ProX EX NAT.

Impact and fatigue resistant plastic for harsh environments

DuraForm FR1200.

Flame retardant

DuraForm ProX FR1200.

Flame retardant

DuraForm ProX EX BLK.

Impact and fatigue resistant plastic for harsh environments

DuraForm ProX AF+.

High stiffness, aluminum-filled Nylon 12 with metallic appearance

DuraForm ProX PA.

Strong, tough polyamide (nylon) material for production parts

DuraForm ProX HST Composite.

A fiber-reinforced engineering plastic, high temperature resistance

DuraForm ProX GF.

A glass-filled engineering plastic with excellent stiffness

DuraForm PA.

Durable polyamide (nylon) material for production parts

DuraForm HST Composite.

A fiber-reinforced engineering plastic, high temperature resistance

DuraForm GF.

A glass-filled engineering plastic with excellent stiffness

DuraForm EX Natural.

Tough, impact-resistant plastic for harsh environments

DuraForm EX Black.

Tough, impact-resistant plastic for harsh environments

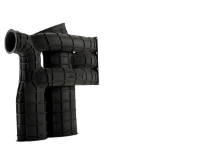

DuraForm TPU Elastomer..

Thermoplastic elastomer material, rubber-like flexibility and functionality

DuraForm Flex.

Durable, rubber-like material

CastForm PS.

Styrene-based, expendable pattern casting material

Selective Laser Sintering (SLS).

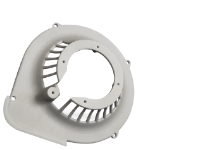

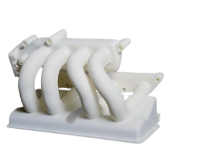

Unlock the potential of Selective Laser Sintering (SLS) for your next project! This advanced 3D printing technology utilizes a laser to fuse powdered materials layer by layer, building intricate, production-grade nylon parts renowned for their durability, complexity, and high-performance capabilities.

Unleash the benefits of SLS:

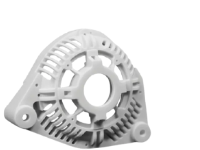

- Toughness built-in: SLS parts excel in demanding environments, withstanding high heat, chemicals, and impact. Ideal for automotive, aerospace, and medical applications.

- Complex geometries made simple: Design intricate features and functional components with ease, thanks to SLS's unparalleled layer-by-layer precision.

- Production-ready parts: SLS delivers durable, end-use parts that rival traditional manufacturing methods, offering low-volume production and mass customization solutions.

- Wide range of applications: Explore the versatility of SLS for jigs, fixtures, tools, investment casting patterns, elastomeric parts, and more.