Accelerate growth with Digital Manufacturing.

Accelerate growth with Digital Manufacturing.

3D printing solutions.

Your parts made to order. Delivered where and when you need them.

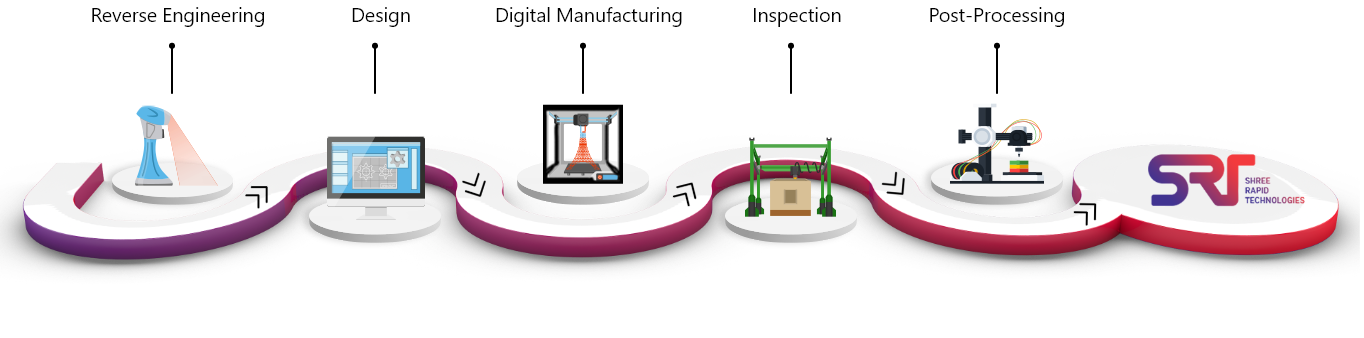

Start where it matters the most.

SRT provides the best in class 3D Printing technology ranging from scanning to designing to printing and finally post processing. With all the processes under one roof, SRT is one of the only few companies providing its clients an end to end solution for Digital Manufacturing.

Our legacy sets us apart!!

At the beginning it was just 2, now we are 60 people strong. In a span of 13 years SRT has grown and played a vital role in transforming the 3D Printing industry in India.

We believe in building the manufacturing sector and see ourselves as the enablers of digital manufacturing in the country.

News & Press

Stay up-to-date with the latest industry news, blogs, and insights on digital design & manufacturing.

Downloads PDF’s

Get your hands on the recent brochures, white papers, and more.

Success Stories

Hear from our clients how they are transforming their manufacturing processes with solutions ranging from digitization, design, inspection and management.

Ready to UnLEARN?

Everything you need to know about 3D Printing Solutions & Applications.

Let's create future, together.

Connect with us today and gain the digital manufacturing advantage!